PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

TPE Car Mat Sheet Extruder Machine - Main Unit" style="max-width:100%; height:auto; margin:20px 0;">

TPE Car Mat Sheet Extruder Machine - Main Unit" style="max-width:100%; height:auto; margin:20px 0;">

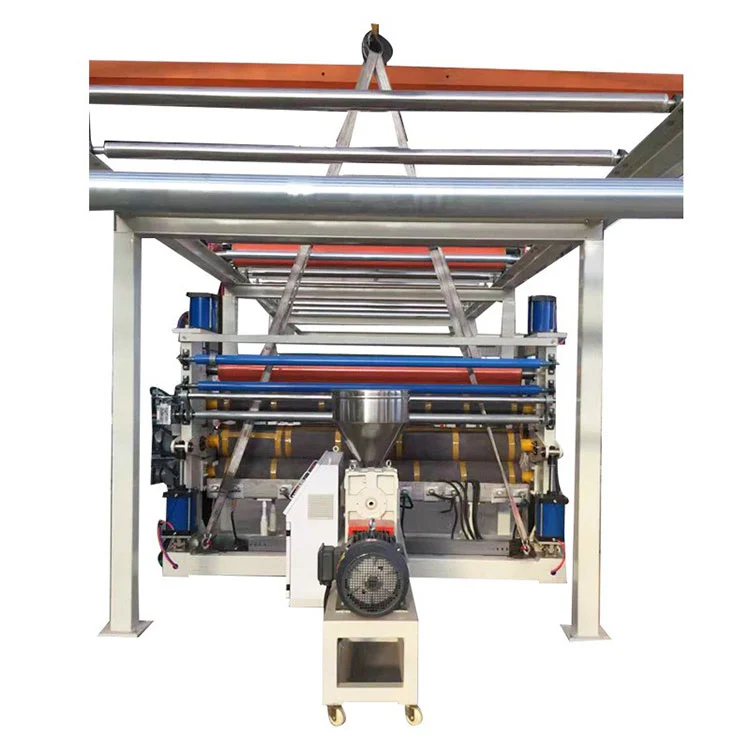

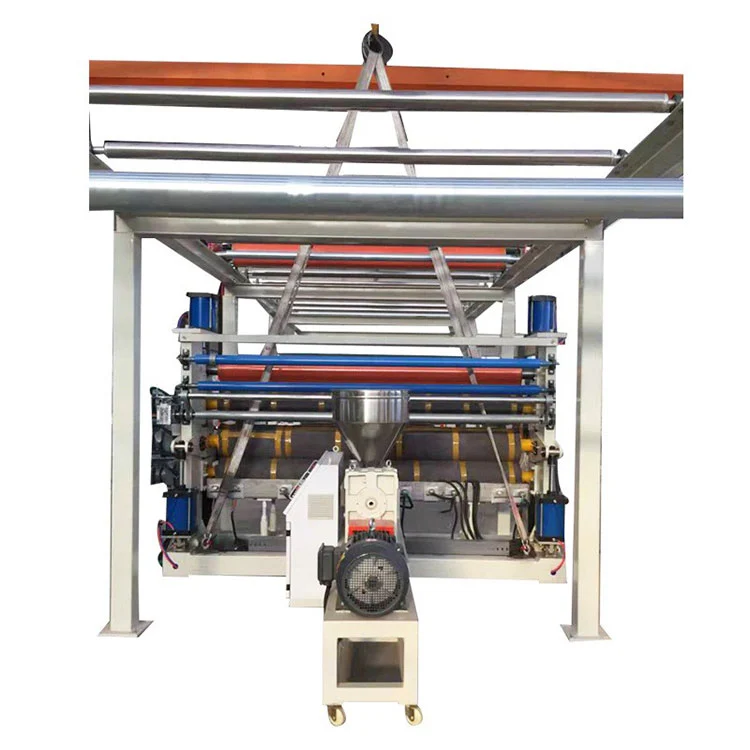

In the competitive world of automotive accessories manufacturing, the demand for high-quality, durable, and environmentally friendly car mats has never been greater. The TPE Car Mat Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. stands as a beacon of innovation in this sector. This sophisticated machinery is specifically engineered to produce thermoplastic elastomer sheets that form the foundation of premium automotive floor mats. Unlike conventional rubber or PVC mats, TPE-based products offer superior flexibility, excellent abrasion resistance, and complete recyclability, meeting the evolving standards of both automotive manufacturers and environmentally conscious consumers.

The manufacturing process begins with raw TPE material being fed into the machine's precision hopper system. Through a carefully calibrated extrusion process, the material is melted, homogenized, and formed into consistent sheets of predetermined thickness and width. What sets this machine apart is its ability to maintain exact dimensional stability while accommodating various TPE formulations, allowing manufacturers to create products with specific hardness levels, colors, and surface textures. The resulting sheets can be precisely cut and molded into car mats that perfectly fit vehicle floor contours, providing maximum coverage and protection.

The TPE Car Mat Sheet Extruder Machine incorporates multiple technological breakthroughs that deliver tangible benefits throughout the production cycle. Its advanced screw design, developed through extensive research and testing, ensures optimal melting and mixing of TPE compounds. This results in sheets with consistent material properties from edge to edge, eliminating weak spots or variations that could compromise product quality. The machine's temperature control system maintains thermal stability within ±1°C, crucial for processing temperature-sensitive TPE materials without degradation.

Durability forms another cornerstone of this machine's value proposition. Constructed with high-grade alloy steels and corrosion-resistant components, the extruder withstands continuous operation in demanding industrial environments. The gearboxes feature precision grinding and hardening processes that extend service life while reducing maintenance requirements. For manufacturers, this translates to fewer production interruptions and lower total cost of ownership over the equipment's lifespan.

Operational efficiency receives significant attention in the machine's design. The automated thickness adjustment system allows quick changes between different product specifications without manual intervention. Integrated sensors continuously monitor sheet dimensions, automatically compensating for any deviations to maintain quality standards. This level of automation not only reduces labor costs but also minimizes material waste, contributing to both economic and environmental sustainability.

Many manufacturers struggle with inconsistent material flow that leads to thickness variations in extruded sheets. The TPE Car Mat Sheet Extruder Machine addresses this through its melt pump system that ensures constant pressure and output, resulting in sheets with uniform thickness profile across the entire width. This consistency is critical for automated cutting and molding processes downstream.

Energy consumption represents another significant concern in extrusion operations. This machine incorporates high-efficiency AC motors and optimized heating systems that reduce power usage by up to 25% compared to conventional extruders. The insulation system minimizes heat loss to the environment, further enhancing energy efficiency while improving working conditions for operators.

| Parameter | Standard Extruder | Eaststar TPE Extruder | Benefit |

|---|---|---|---|

| Screw Diameter | 90-120mm | 80-150mm (customizable) | Wider processing range |

| L/D Ratio | 30:1 | 36:1 to 40:1 | Better melting & mixing |

| Output Capacity | 300-500 kg/h | 350-800 kg/h | Higher productivity |

| Thickness Tolerance | ±0.2mm | ±0.1mm | Superior consistency |

| Energy Consumption | 0.35-0.45 kWh/kg | 0.25-0.35 kWh/kg | Lower operating costs |

Automotive parts manufacturers represent the primary users of this advanced extrusion technology. These companies supply original equipment manufacturers (OEMs) and aftermarket distributors with custom-fitted car mats that meet rigorous quality standards. The ability to produce TPE sheets with specific characteristics allows them to create products ranging from basic protective mats to premium offerings with integrated features like anti-slip surfaces, odor resistance, and custom color matching.

Specialty mat producers serving commercial vehicle segments benefit equally from this technology. Fleet operators for delivery services, taxis, and ride-sharing companies require durable mats that withstand heavy use while maintaining appearance. The TPE Car Mat Sheet Extruder Machine enables production of heavy-duty mats with enhanced wear resistance and easy-cleaning properties, extending product life in high-traffic applications.

Entrepreneurs entering the automotive accessories market find this machine particularly valuable for its versatility and relatively compact footprint. The system's quick changeover capabilities allow small-batch production of customized mats for specific vehicle models, enabling businesses to serve niche markets without maintaining large inventories. This flexibility provides a competitive edge in responding quickly to market trends and customer preferences.

Operating the TPE Car Mat Sheet Extruder Machine brings a sense of assurance to production managers and floor operators alike. The intuitive control interface, with its color touchscreen and logical menu structure, reduces training time and minimizes operational errors. Real-time monitoring of key parameters like melt pressure, temperature profiles, and output rates provides complete visibility into the production process, enabling proactive adjustments before issues affect product quality.

For business owners, this equipment represents more than just a production tool—it's a partnership in growth. The reliability of Qingdao Eaststar Plastic Machinery Co., Ltd.'s engineering means fewer unexpected downtime incidents that disrupt delivery schedules and damage customer relationships. The consistent quality output strengthens brand reputation in the marketplace, allowing manufacturers to command premium pricing for their products while reducing returns and warranty claims.

Maintenance technicians appreciate the machine's accessibility features that simplify routine servicing and component replacement. strategically located access panels, color-coded wiring, and comprehensive documentation reduce repair times when maintenance is required. The availability of spare parts and technical support from the manufacturer further enhances operational confidence, ensuring that production targets are consistently met.

While many extruders claim capable TPE processing, the TPE Car Mat Sheet Extruder Machine incorporates specific design elements that deliver measurable performance advantages. The patented screw geometry achieves superior melting efficiency without excessive shear heat, preserving the physical properties of sensitive TPE compounds. This results in finished sheets with better elasticity recovery and longer service life in the final product.

The integrated vacuum calibration system represents another technological leap forward. This feature ensures precise dimensional control during the cooling phase, eliminating the bowing or warping issues that plague conventional extrusion lines. The resulting sheets lay perfectly flat for subsequent processing steps, improving yield rates in cutting and molding operations.

Connectivity features position this machine at the forefront of Industry 4.0 manufacturing. Ethernet and optional wireless interfaces enable integration with factory management systems for real-time production monitoring, predictive maintenance scheduling, and remote troubleshooting. These capabilities transform the extruder from a standalone unit into an intelligent component of an optimized manufacturing ecosystem.

What types of TPE materials can this machine process?

The TPE Car Mat Sheet Extruder Machine handles a wide range of thermoplastic elastomer compounds including SBS, SEBS, and TPU-based formulations. The versatile screw design and temperature control system accommodate materials with Melt Flow Index values from 1 to 50 g/10min and Shore hardness ranging from 30A to 95A. This flexibility allows manufacturers to switch between different material grades with minimal adjustment time.

How does the machine ensure consistent sheet thickness?

Multiple systems work in concert to maintain dimensional accuracy. The precision gear pump provides consistent melt pressure to the die, while automatic thickness gauges continuously monitor the sheet profile. The data feeds into a closed-loop control system that makes micro-adjustments to the haul-off speed and die gap, compensating for any variations in real-time. This integrated approach delivers thickness tolerances within ±0.1mm across the entire sheet width.

What safety features are incorporated into the design?

Operator protection begins with comprehensive machine guarding that prevents access to moving parts during operation. Emergency stop buttons positioned at multiple locations allow immediate shutdown if needed. The electrical system includes overload protection, ground fault detection, and thermal monitoring to prevent hazardous conditions. For the material itself, ventilation systems control fume emission during processing, maintaining safe working environment standards.

How quickly can product changeovers be accomplished?

Changeover time depends on the specific differences between products, but the machine's design prioritizes rapid transitions. The quick-disconnect die system allows complete die changes in under 30 minutes for major product variations. For minor adjustments like thickness changes, the automated control system can implement new parameters in seconds. Recipe storage functionality saves all settings for different products, enabling one-touch recall of established configurations.

What kind of training and support does Qingdao Eaststar provide?

Comprehensive training programs cover operational procedures, routine maintenance, and troubleshooting techniques. On-site instruction during commissioning ensures your team develops proficiency with the specific machine configuration. Ongoing technical support remains available through multiple channels including phone, email, and remote connectivity options. Spare parts availability and service technician dispatch complete the support package for uninterrupted operation.

Can the machine be customized for specific production requirements?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers extensive customization options to match particular manufacturing needs. Available modifications include specialized screw designs for unique material formulations, alternate width capabilities from 1000mm to 2500mm, and integration with downstream equipment like embossing units or cutting systems. The modular construction approach allows tailoring the machine configuration during the manufacturing process without compromising structural integrity or performance.

What is the typical installation and commissioning timeline?

From order confirmation to operational status typically requires 90-120 days depending on machine specifications and customization requirements. Factory acceptance testing occurs before shipment to verify performance meets specifications. On-site installation by qualified technicians usually completes within 5-7 working days, followed by 2-3 days of production trials and operator training. The comprehensive process ensures smooth transition to full production with minimal disruption to existing operations.