PE PP Sheet Extruder Machine,PVDF PEEK Sheet Extruder Machine,PA POM Sheet Extruder Machine,Hard PVC Transparent Sheet Extruder Machine,Soft PVC Transparent Sheet Extruder Machine,ABS Board Extruder Machine,PE PP Board Extruder Machine,PVC Sheet Extruder Machine,PS Sheet Extruder Machine,TPU Sheet Extrusion Machine,PVC Board Extruder Machine,Biodegradable Sheet Machine

Welcome to the world of precision engineering with Qingdao Eaststar Plastic Machinery Co., Ltd. Our PVDF Sheet Extruder Machine represents a leap forward in industrial manufacturing, designed to handle the demanding requirements of high-performance polymer processing. Imagine a machine that seamlessly transforms raw PVDF (Polyvinylidene Fluoride) materials into uniform, high-quality sheets used across various industries. From chemical-resistant linings to electrical insulation components, this machine is the backbone of reliable production lines, ensuring consistency and durability in every sheet produced.

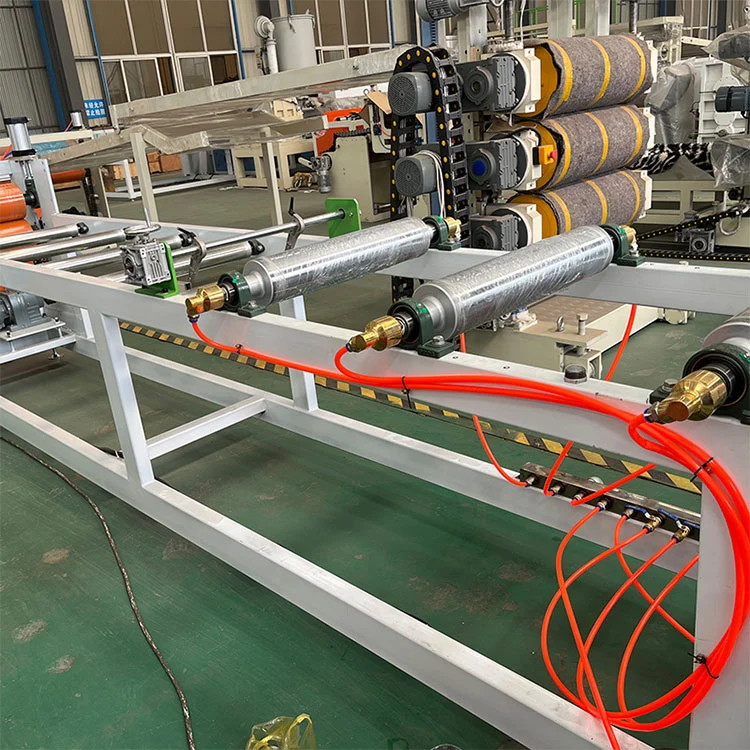

At the core of our PVDF Sheet Extruder Machine lies a blend of cutting-edge technology and robust design. Engineered for efficiency, it features an optimized screw and barrel system that minimizes material degradation, resulting in sheets with exceptional mechanical strength and chemical resistance. The intuitive control interface allows operators to fine-tune parameters with ease, reducing setup times and enhancing productivity. Moreover, Qingdao Eaststar Plastic Machinery Co., Ltd. backs every unit with rigorous quality checks and comprehensive support, ensuring long-term reliability and peace of mind for businesses.

Many manufacturers face issues like inconsistent sheet thickness, high energy consumption, and frequent downtime. Our PVDF Sheet Extruder Machine addresses these pain points head-on. For instance, in chemical processing plants where corrosion resistance is critical, traditional machines often falter, leading to costly replacements. With our solution, advanced temperature control and anti-corrosion materials ensure stable performance even in harsh environments. Below is a snapshot of key parameters that highlight its capabilities:

| Parameter | Value | Benefit |

|---|---|---|

| Output Capacity | Up to 500 kg/h | High throughput for large-scale projects |

| Screw Diameter | 80-150 mm | Versatile for various sheet dimensions |

| Power Consumption | Optimized to reduce by 15% | Lower operational costs and eco-friendly |

| Sheet Thickness Range | 1-20 mm | Precision for diverse application needs |

| Temperature Control Accuracy | ±1°C | Ensures uniform quality and minimal waste |

This machine is ideal for industries such as chemical engineering, construction, automotive, and electronics. Picture a factory producing corrosion-resistant tanks or a workshop fabricating insulating components for high-voltage equipment—our PVDF Sheet Extruder Machine fits seamlessly into these settings. It caters to engineers, production managers, and business owners seeking to enhance their manufacturing capabilities without compromising on quality or efficiency.

Using our extruder machine brings a sense of empowerment and relief. Clients often report reduced material waste, fewer machine breakdowns, and a noticeable boost in output consistency. For example, a user in the semiconductor industry shared how switching to our machine eliminated production bottlenecks, allowing them to meet tight deadlines with superior product integrity. It's not just about making sheets; it's about building trust in every layer.

Compared to standard extruders, our PVDF Sheet Extruder Machine from Qingdao Eaststar Plastic Machinery Co., Ltd. offers unique features like a modular design for easy maintenance and customizable configurations to match specific production lines. While others may focus on basic functionality, we integrate smart monitoring systems that predict maintenance needs, reducing unexpected downtime. This forward-thinking approach sets us apart, making it a preferred choice for forward-looking enterprises.

What is the typical lifespan of this extruder machine?

With proper maintenance, the machine can operate efficiently for over 10 years, thanks to its high-quality components and robust construction designed for continuous use in industrial environments.

Can it handle other materials besides PVDF?

While optimized for PVDF, it is versatile enough to process similar fluoropolymers with minor adjustments, though we recommend consulting our team for specific material compatibility to ensure optimal performance.

How does the energy efficiency compare to older models?

Our machine incorporates advanced drive systems and insulation, typically reducing energy consumption by 15-20% compared to conventional models, which translates to significant cost savings over time.

Is training provided for operators?

Yes, we offer comprehensive training sessions and detailed manuals to help your team master the controls and maintenance procedures, ensuring smooth integration into your workflow.

What kind of after-sales support is available?

We provide 24/7 technical support, routine maintenance services, and easy access to spare parts, all backed by Qingdao Eaststar Plastic Machinery Co., Ltd.'s commitment to customer satisfaction.

Can the machine be customized for specific sheet sizes?

Absolutely, we offer customization options for screw configurations, die designs, and control settings to meet unique production requirements, ensuring the machine adapts to your needs.